Custom built TEM cell for EMC measurements

EMC tests are scary: often they are near the end of electronics development, and an extra prototype round can really mess up schedules. How nice would it be to check for obvious issues already in the first prototype?

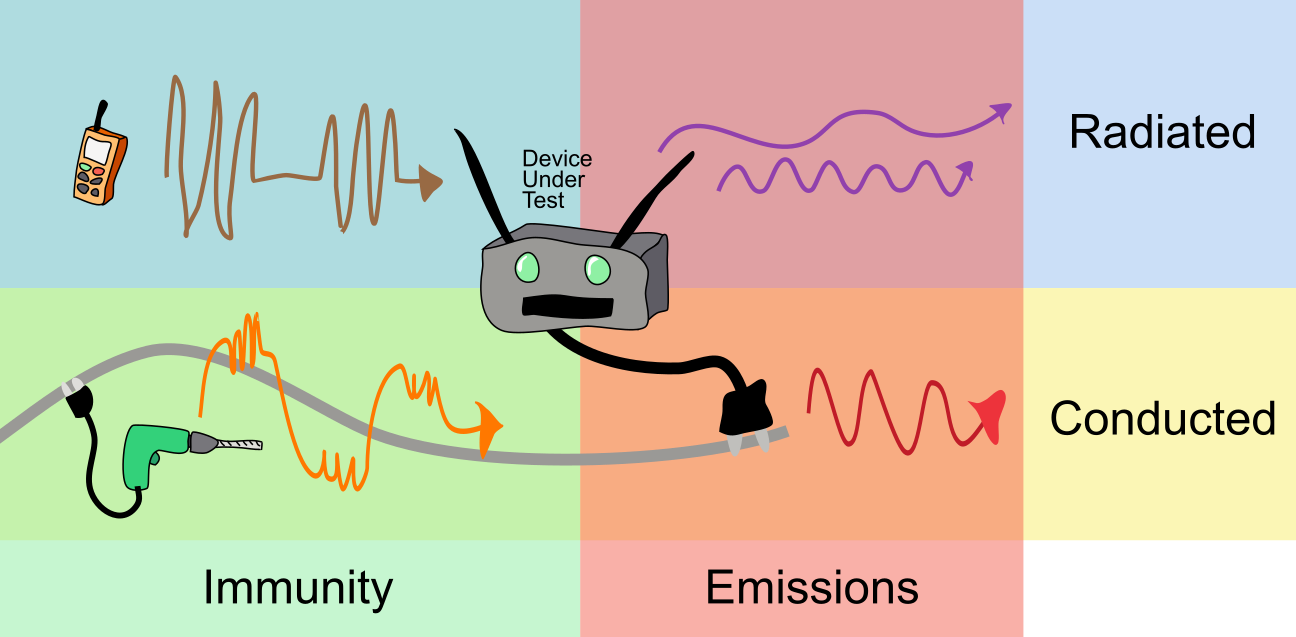

The basic goal is to limit unintentional RF radiation from one device messing up the operation of another device. The EMC tests have two roles, and two modes: emissions and immunity, conducted and radiated. Emissions are what the device under test puts out to the world, while immunity is how it reacts to noise from outside. Conducted is through cables, and radiated is by radio waves.

Standards compliance is checked in shielded rooms with carefully calibrated equipment. Full test labs are expensive to use and unwieldy for quickly testing how changes affect things. For desktop level, the basic tools available for emission measurement are current probes, near field probes and TEM cells. For immunity checking, RF power amplifiers are used to create disturbances to check if it causes issues in the device.

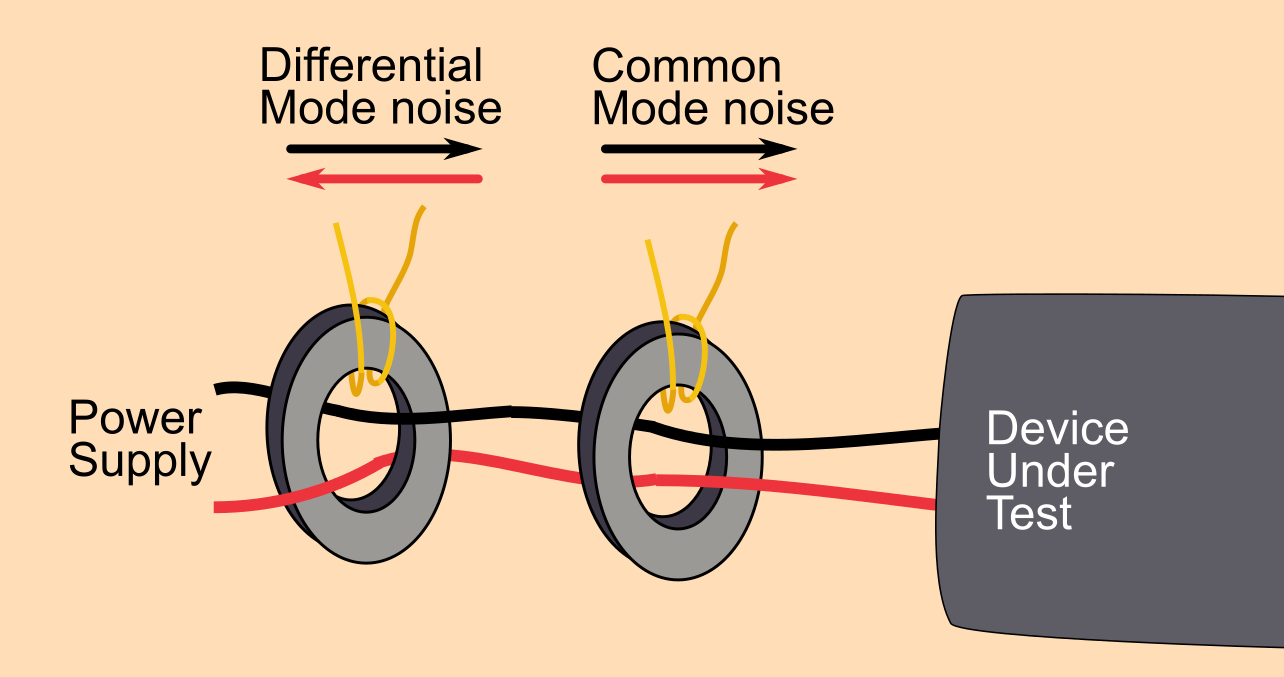

Current probes are useful for checking common mode and differential mode emissions on cables. Using a LISN between the power supply and the device being tested makes the results comparable to applicable standards. Not all EMC standards require conducted emission testing, but the emissions will still show up as radiated noise. Conducted emissions are typically easy to fix by adding some ferrites, but it is cheaper and more effective to put the ferrites on PCB rather than on the cable. So definitely worth an early check.

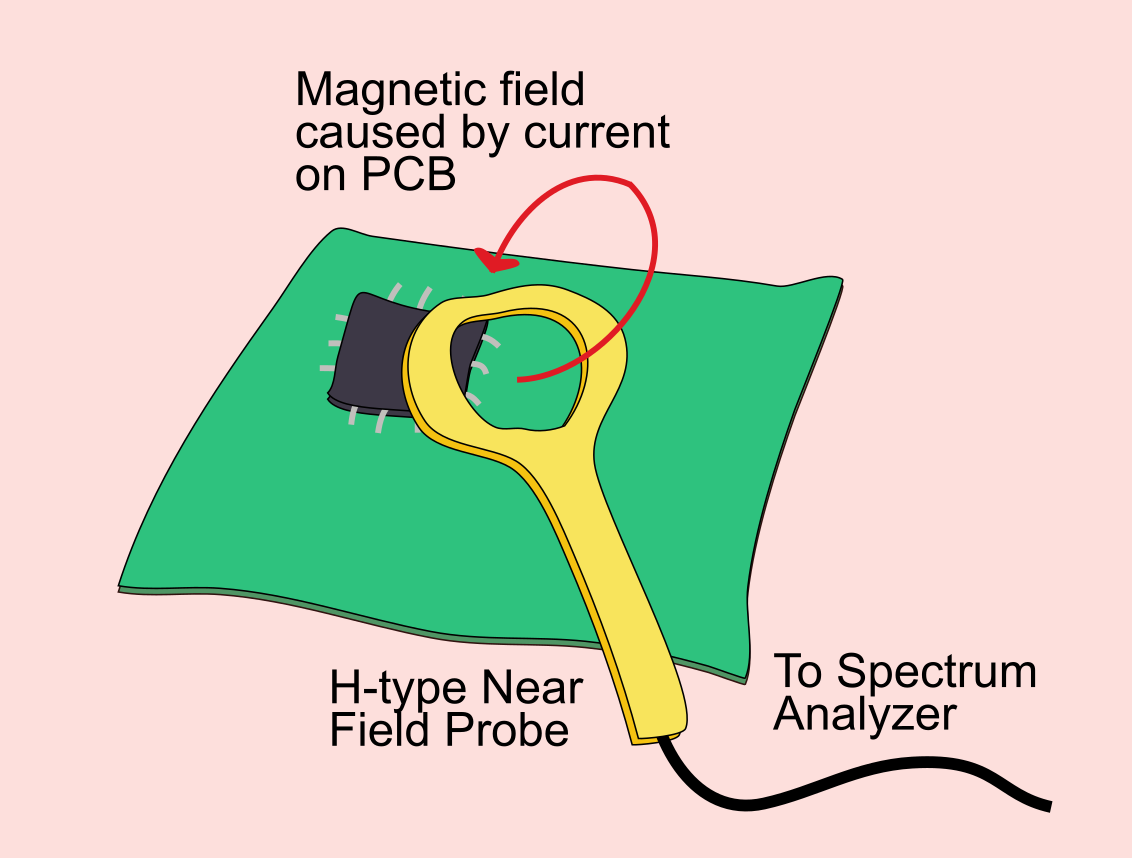

Near field probes can pinpoint noisy parts of a device, but they do not indicate how strong the noise will be further away. They are an useful tool once you know you have an EMC problem at particular frequency, but cannot tell whether you do or not. Near field probes are easy to build yourself.

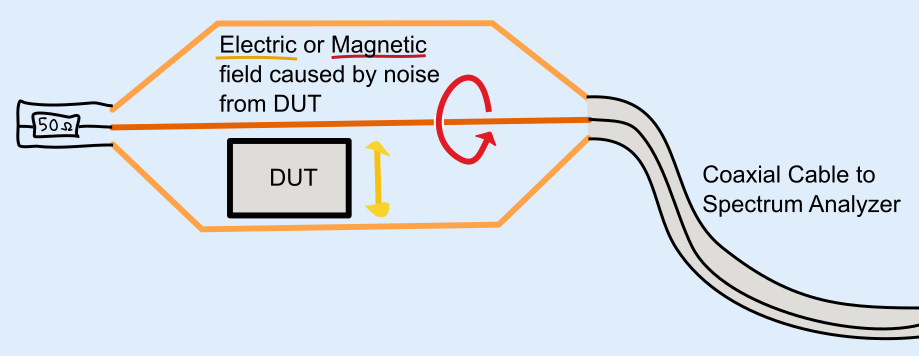

TEM cells are the closest you can get to actual radiated emissions and immunity testing in normal electronics laboratory. They are even allowed as the official measurement method in some EMC standards. TEM cell is like an expanded coaxial cable that is wide enough to put your device inside of. Any electric field between the shield and center conductor, or any magnetic field perpendicular to center conductor is then transferred to the output connector. Other end is terminated to a 50 ohm dummy load to prevent reflections.

TEM cells provide reasonable correlation to the far-field emission limits, but are still affected by device size and orientation.

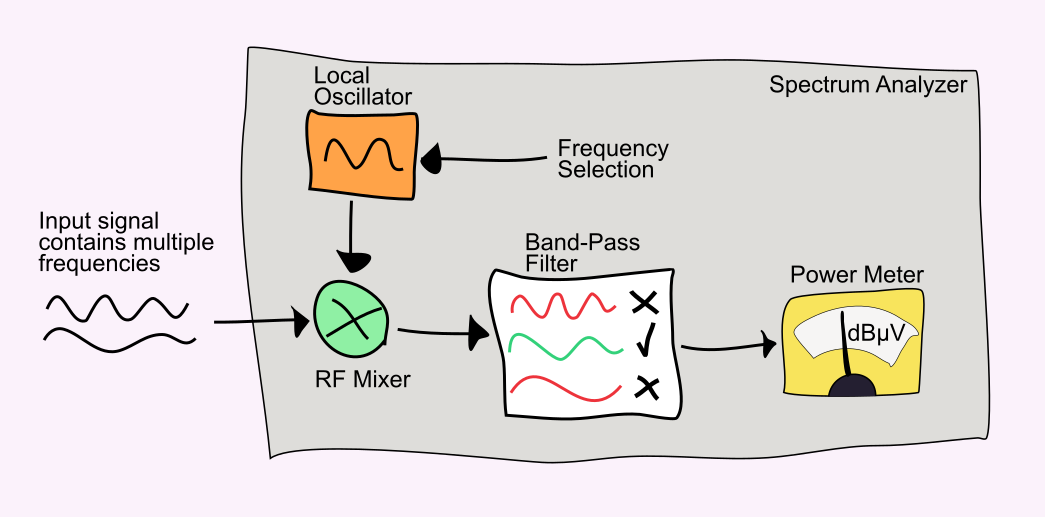

All of these still require a device to actually measure the signal levels. The specialized instrument for the purpose is called an EMI receiver, which is a high sensitivity radio receiver that can be tuned over a wide frequency range. For pretesting, a spectrum analyzer is a more affordable choice and has many other uses besides EMC testing. In a pinch, a digital oscilloscope with FFT function can be used, but it will require a preamplifier. The signal amplitudes of interest are less than 1 millivolt. Whatever instrument is used, the goal is to be able to measure the signal amplitude separately at each frequency.

The articles below document the equipment I have built for my own electronics workbench. The total cost of materials is around 100 EUR, and for spectrum analyzer I'm using the 150 EUR tinySA Ultra.

TEM cell construction

Building a TEM cell is easy in principle: it is just a metal box. But it does require careful dimensioning to work well, and many of the formulas online are just plain wrong.

Integrated LISN

Measurement of conducted emissions is as simple as measuring either the voltage or current at the cables going to the device. Typically this is done for the power cables. Most common way is to measure voltage when power is supplied through a line impedance stabilization network.

Usage experiences

TEM cells are best suited for eliminating highest noise components early in prototype cycle, and for testing improvements after a failed EMC test. So far I have only tested prototypes, but the setup has already proven useful at spotting mistakes early.