Pantograph

Eager to try out the CNC mill, I decided to make a pantograph as a present to my nephew. Pantograph is a device that uses four linked arms to constrain the movement of two pens. When one pen is traced over a shape, the other pen draws the same shape enlarged or miniaturized.

Design

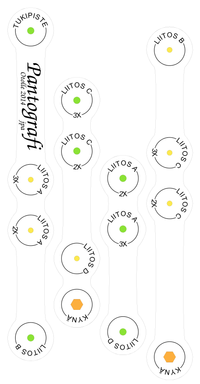

The basic design of a pantograph is simple geometry. When the arm lengths are calculated correctly, the distance from the fixed point to the "large pen" will always be a constant multiple of the distance to the "small pen". For accurate functioning, it is important that the fixed point stays in place, and that the links between the arms move smoothly but without much play.

I wanted to make the device easy to set up and to store away, so unlike some other versions online I didn't make any permanent joints. By carefully deciding the stacking order of the arms it was possible to make it stay together just by gravity. At the link between the two long arms there is a piece of teflon rod that will slide against the paper, to keep the arms horizontal.

The links between the arms are made of 4 mm brass rod. One half of the rod is threaded and screwed into the wood, and the other half is polished and inserted to a hole in the other arm. Each arm has a text around the hole/tap, identifying the link: e.g. "Link A 2X" or "Fixed point".

Finally, the pens are attached to the arms by a friction fit. A hexagonal hole fits a typical 6 mm wide pencil. In retrospect, I probably should have bought some extra soft 9B pencils in order to make a darker mark on the paper. The weight of the arms does not apply quite enough pressure for a pencil of normal hardness.

Manufacturing

Designing the layout in Inkscape was easy enough. I chose to use MakerCAM to make the G-code for the CNC machine. This worked fine, though MakerCAM does generate quite inefficient code at times. It tends to spend much more time just moving the CNC around in the air than actually milling anything.

Some learning experiences later (always tighten mounting screws evenly, and better to zero the Z in the middle of the workpiece instead of at a corner), I had the arms machined and complete with engravings. A little bit of sanding and they were ready to use.

For the fixed point, I used a stack of heavy steel washers. The main axis goes through them and stays in place with two nuts. After tightening, I covered the whole thing in a large blob of Oogoo. After a plain white blob turned out quite boring and ugly, I painted on a few ducks (always a sure way to make things happier looking).

Afterthoughts

The mechanical structure works quite well. Also the disconnectable links are great - it is possible to assemble the device in many unexpected ways, which will make skewed or mirror images. The pencil hardness limits the images made, but that is easy enough to replace if this turns out to be a good toy.

– Petteri Aimonen on 3.8.2014