Automatic fume removal trigger for JBC soldering station

I decided to upgrade from TS-100 soldering iron to JBC BT-2BWA. I used to have my TS-100 on the same switch as fume removal, but decided to make a more advanced automatic trigger for the JBC station.

First impressions on JBC station

I have been using TS-100 for a couple of years now, and especially after upgrading to IronOS it has performed very well. With lead-based solder I would have had no need to upgrade. With lead-free alloys requiring about 40°C higher temperatures it has begun to feel a bit underpowered.

The JBC station is obviously better and more powerful than the TS-100, but surprisingly the difference is actually not that huge. It is most noticeable in the warm-up time: 10 seconds vs. 20 seconds, and with large thermal load such as 4-layer boards. Ergonomically the C245 handle has shorter distance to the tip, making it easier to position accurately.

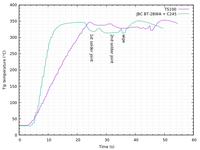

I tried to measure the tip temperature using a thermocouple, but the sensor I have is too large to be put between the tip and the solder joint. So I mounted it on the opposite side of the tip (C245-907 for JBC, TS-BC2 for TS-100) with some thin metal wire. For a test, I soldered two large through-hole pads with leadfree solder, then wiped the iron on the metal sponge. This resulted in a surprising effect: the temperature drop was actually larger for JBC, but the solder melted much faster. I think the explanation is that the JBC tip conducts heat better, resulting in higher temperature drop on the opposite side.

On the negative side, most striking thing is the large size of the JBC station compared to TS-100. I also quite liked the "boost" button on TS-100, which made it easy to quickly increase heat if a joint was not melting.

Fume removal trigger

So far my fume "removal" system has been simply a fan that blows sideways over my soldering mat. This blows the fumes out of my face and hopefully lets most of it settle elsewhere than in my lungs.

With TS-100, the fan was on the same switch as the soldering iron. At least I didn't have to turn it on separately, but it would be blowing all the time even when the iron is in standby.

The JBC station has automatic detection of when the iron is in its stand, and two LEDs to indicate operating mode. I decided to add a photodiode on top of the green "in use" LED, which would then turn on the fan when needed. If I eventually end up upgrading to actual fume removal system, I could use the same trigger method.

Schematic and parts

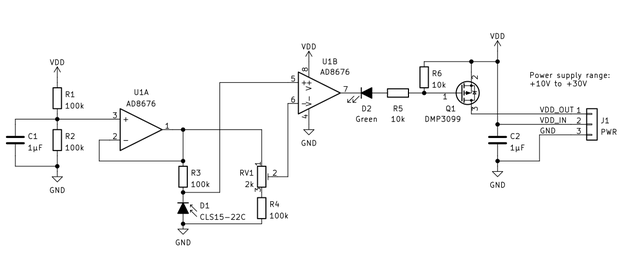

The schematic is a simple comparator. The photodiode is connected in series with R3, and the voltage drop over the resistor corresponds to the current through the photodiode, which in turn corresponds to light intensity. U1B compares this to the threshold set by RV1 trimmer. Because the opamp used does not have rail-to-rain input, U1A is used to create a virtual ground in midway between supplies to bias the inputs.

I chose the parts based on what I happened to have left-over from other projects. The dual high-precision AD8676 opamp is an overkill for this application. I used half of it as a buffer for the virtual ground, but reducing R1/R2 to 10 kilo-ohm would have allowed a single-amp chip to be used also. Rail-to-rail outputs make driving the MOSFET easier.

The sensitivity depends on R3 value. The larger the series resistance, the smaller amount of light will trigger the sensor. The photodiode also has some leakage current without light, so if any setting of RV1 does not turn the output off, R4 should be decreased.

When the photodiode current exceeds the setpoint, opamp U1B output goes to GND. This in turn pulls down the gate of Q1 P-channel MOSFET, turning it on. The R5/R6 divider limits the maximum gate voltage to avoid exceeding MOSFET specs. The D2 indicator LED is lit with the current going through the divider.

PCB and mounting

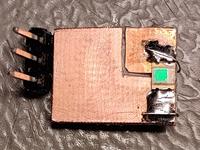

I made the PCB with a hobby knife. The photodiode is on the underside and rest of the parts are on the top side. Black heatshrink was added to make it look cleaner and to protect from short-circuits.

The sensor PCB mounts on top of the green LED. The indicator LED on board kind-of takes the place of the original indicator.

Video and design files

Here is a quick demonstration video. The fan is visible behind the station.

In case you want to remake this, the KiCAD schematic is available here.

– Petteri Aimonen on 29.12.2021