Noise isolation box

Using a CNC router in an apartment has a few limitations, namely noise and chips. To contain these, I built an insulated, air-tight box. To further make it fit in with the furniture, the lid is upholstered and acts as a bench.

Construction

The bottom and top are made of 15 mm plywood, the side walls of 5 mm plywood and the front door of 16 mm MDF. The plywood panels are screwed into a frame made of 2x4 cm wood beams.

The front door swivels on two cabinet hinges, which allow it to rest evenly on the floor when open. This is useful so that one can kneel on it while adjusting the workpieces or machine, without damaging either the floor or the door.

At first I planned to have a separate compartment for the control unit, to keep it free of the dust. It turned out too small, so I just removed the divider. The control box now has some fabric glued to air intakes in order to keep the dust out.

Upholstery

The lid was upholstered with 4 cm of heavy plastic foam and a red fabric. Upholstering a rectangular piece was quite straightforward, only the corners required some thought with the folds. Basically just start from the centers of the long sides and work towards the corners.

Insulation

All inner corners were made airtight with silicone. After that, I installed 2 cm of sound insulation foam on all inside walls, on the front door and on the underside of the lid. On the bottom I put a two layers, totalling 4 cm of foam, and on that two heavy garden tiles. The garden tiles were based on experimentation, and help to damp the vibrations.

The lid and the door have rubber sealing strips on every edge and on both sides. The rubber-to-rubber contact seals well and allows passing cables through the gap.

Electronics and heat management

Putting a lot of electronics in an insulated box has its own problems when it comes to heat management. Computationally, the box can dissipate about 20 watts of energy at a reasonable temperature difference of 20°C. However, the router uses an average of about 100 watts of electricity when milling, practically all of which goes to heat.

Fortunately opening the lid to see the progress also lets out most of the warm air, and in practice I haven't had any overheating trouble so far.

Just to be safe, I decided to install an outlet with overtemperature cutoff inside the box. I wanted something that is already certified to work with mains electricity, and is easy to reset when needed. However, I didn't want a plain thermostat - the protection switch should remain open until it is manually turned back on.

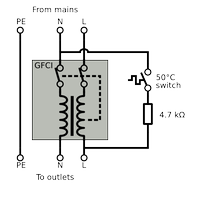

A ground fault circuit interrupter was a perfect match for this need. By connecting a cheap thermostat switch crosswise over the GFCI, one can make it trip whenever the thermostat activates. The GFCI by design is spring-loaded and will not return to connected state without manual intervention. The connection is the same as is used by the built-in test button of the GFCI.

I used a 50°C thermostat switch. This should also provide some fire protection, as none of the contained materials will ignite below 300°C. A local flame in an air-tight box will extinguish quickly when no extra energy is added.

Finally, a cheap led strip at one end provides enough light to the insides to allow easy monitoring of the routing progress.

Outcome

The box does deaden the noise quite well, atleast when tested with a vacuum cleaner as in the video below.

If your browser does not support WebM for video, you can either watch on YouTube or download the video.

However, some of the vibrations from the router still get through. Mostly this is because the 5 mm plywood walls are too thin and not heavy enough. Some 20 mm MDF or better yet, cork would have avoided the resonances.

With heavy milling, such as aluminum or milling wood with a 8 mm bit, the noise gets somewhat annoying. But in my normal usage with light milling of plastic, the router is less noisy than our dishwasher. Also dust and chips stay nicely inside the box and are easy to vacuum off afterwards.

So far the longest runs I have done have been 2 hours, and with the occassional opening of the lid there seems to be no trouble with heat.

– Petteri Aimonen on 27.9.2014